Thermal Test Device ANSI Z97.1

Specimens

Three specimens, each 12 inches by 12 inches (310 mm x 310 mm)

Application

This test shall be made to determine the probable effect of exposure to high temperature and humidity conditions for a long period of time.

Procedure

Three 12 inch by 12 inch (305 mm x 305 mm) flat specimens, as submitted, shall be subjected to an extended heat history through bake testing in an oven or boil testing.

The thermal test may be conducted either in a heating chamber or boiling water. The test temperature is 212°F ± 4°F (100 °C ± 2°C). The specimens shall be conditioned to a uniform test temperature between 65°F and 85°F (18°C and 29°C) for at least 4 hours with separation to permit free air circulation prior to rating.

(1) Boil Testing

Samples are immersed, vertically, in water at 150°F ± 10°F (65.6°C ± 6°C) for 3 minutes and then quickly transferred to and similarly immersed in boiling water. The specimens shall be kept in the boiling water for 2 hours and then removed.

(2) Bake Testing

Samples are placed in a preheated chamber with samples not contacting the walls of the chamber and allowing for free flow of air around each specimen with the exception of the racking mechanism. The chamber is allowed

Interpretation of Results

The glass itself may crack in this test, but no bubbles or delaminations shall develop more than 0.5 inch (12 mm) from the outer edge of the specimen or from any crack that may develop. Any specimen in which the glass cracks to an extent confusing the results shall be discarded without prejudice, and another specimen shall be tested instead.

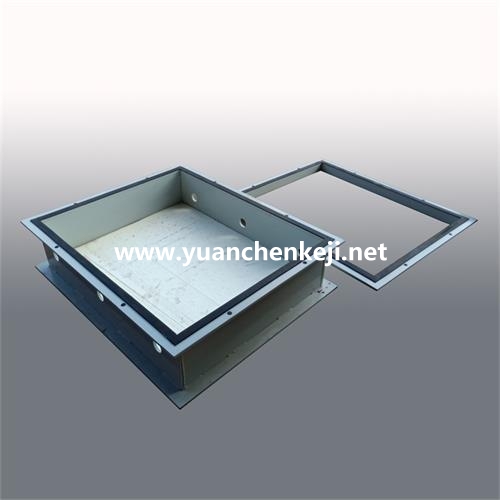

1: cover 2: sample holder 3: cabinet 4: heating rod 5: Power cord

6: drain hole 7: Probe 8: Power distribution cabinet

9: Temperature control table 10: power switch 11: Distribution cabinet lock

Specification

Related Standard:

- EN ISO 12543 – 4 Glass in building -Laminated glass and laminated safety glass – Part 4: Test methods for durability – Clause 5 High-temperature test

- AS/NZS 2208 Safety glazing materials in buildings – Appendix F Boil Test

- GB 15763.3 Safety glazing materials in building Part 3:Laminated glass – Clause 7.8 Heat resistance test

- ANSI Z97.1 Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test – Clause 5.3.2 – ( 1 ) Boil Test

Data:

- Power: 220V 50Hz 3Kw (Customized)

- Outside Size: 430mm*290mm*575 mm

- Inner Size: 400mm*255mm*480mm

- Rack:340mm*235mm*350mm

- At most 6 samples with 300mm*300mm

Scope:

- Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling

Principle:

- Specimens are immerse in hot water and boiling water for specified period of time and inspect bubbles and others defects

Apparatus:

- The apparatus include two water baths, each of sufficient size to hold the test specimen fully immersed vertically on edge for the duration test.

Samples:

- Three specimen of size 300mm*300mm manufacture in a manner identical with impact test specimens and of like thickness shall be tested.

- These specimens may be cut from production samples of the size and thickness submitted for impact testing.

- For heat strengthened or toughened laminated glass, test specimen may be cut from a similar original sheet of annealed laminated glass

Procedure:

- Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66°C±3°C for 3 min

- Quickly transfer the specimens to a bath of water maintain at boiling point. Immerse the specimens vertically on edge for 2 h

- Remove the specimens and examine for the bubbles and others defects