Glazing Test AS/NZS 2208

Complete testing equipment for Safety Glazing Materials Test by AS / NZS 2208

Flatness Requirements

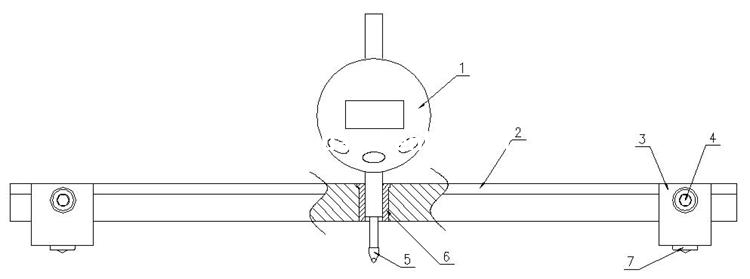

Portable flatness measuring instrument for tempered glass

1, Display table 2, Support plate 3, Support block 4, Fixing bolt 5, Measuring head

6, Fixing part 7, Supporting foot

Application:

- Measurement of arcuate form and wave form of toughened glass

Technical parameters:

- Resolution: 0.01mm

- Measuring Span: 300mm-12000 mm ( Customized)

- Working Temperature: 0~+40℃

- Working Humidity: ≤80%

Instruction:

- Adjust the measurement and set up to track the maximum data. Adjust the span of the support block according to request.

- Adjust the position of measuring head, to ensure that the measuring head is beyond 2mm-3mm of the plane of three support feet.

- Gently stick the surface of the glass to ensure that three supporting feet are able to touch the glass.

- Slide the measure location and read the data.

Product features:

- Continuous measurement and monitoring of the flatness of the glass, data display and recorded.

- Simple operation, fast measurement, low cost, widely used in the flatness measurement of glass.

- The specifications of the equipment are various; the measuring span (300mm, 500mm, 800mm, 1000mm, and 1200mm) can be customized according to customers’ requirements.

Impact Test Apparatus

Samples: 1900 mm * 860 mm

Test Frame: 2480 mm * 1500 mm

Shot Bag Impactor: 46 kg

76 mm diameter sphere, 30 N

FRAGMENTATION TEST

Broken pen

Mass: 75 g±0.3 g

Radius of curvature of the point: 0.2 mm±0.05 mm

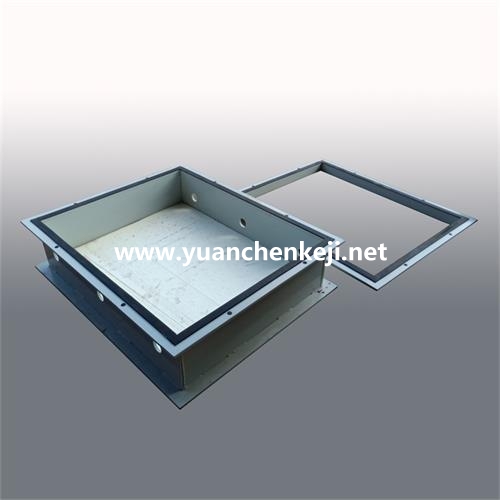

Boil Test

Device for determining the effect of exposure of safety glazing material to temperature and humidity conditions by boiling

Related Standard:

- EN ISO 12543 – 4 Glass in building -Laminated glass and laminated safety glass – Part 4: Test methods for durability – Clause 5 High-temperature test

- AS/NZS 2208 Safety glazing materials in buildings – Appendix F Boil Test

- ANSI Z97.1 Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test – Clause 5.3.2 – ( 1 ) Boil Test

Data:

- Power: 220V 50Hz 3Kw (Customized)

- Outside Size: 430mm*290mm*575 mm

- Inner Size: 400mm*255mm*480mm

- Rack:340mm*235mm*350mm

- At most 6 samples with 300mm*300mm

Scope:

- Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling

Principle:

- Specimens are immerse in hot water and boiling water for specified period of time and inspect bubbles and others defects

Apparatus:

- The apparatus include two water baths, each of sufficient size to hold the test specimen fully immersed vertically on edge for the duration test.

Samples:

- Three specimen of size 300mm*300mm manufacture in a manner identical with impact test specimens and of like thickness shall be tested.

- These specimens may be cut from production samples of the size and thickness submitted for impact testing.

- For heat strengthened or toughened laminated glass, test specimen may be cut from a similar original sheet of annealed laminated glass

Procedure:

- Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66°C±3°C for 3 min

- Quickly transfer the specimens to a bath of water maintain at boiling point. Immerse the specimens vertically on edge for 2 h

- Remove the specimens and examine for the bubbles and others defects

Various of testing equipment for safety glazing

U Value Meter For IG

Ball Drop Test Device:

Pummel Test Device:

Shot Bag Impact Testing Frame:

Head Form Test Device

PV Load Test Equipment

Pneumatic Tyres Device

Forced Entry Resistant Glass Test Device

Insulating Glass Dew Point Meter

Hard/Soft Pendulum Shock Test for Lifts

Laminated Glass High Temperature Test Oven

Tempered Glass Flatness Measuring Instrument

Impactor for building Glass and Metal Guardrail

Hard and Soft Body Impactors for Opaque Wall Components

Portable on-site Comprehensive Measurement Instrument for Energy-saving Glass