Laminated Glass Heat Resistant

Boiling Device for Heat Resistance Test

Water bath apparatus of Boil test for safety glazing materials in Building

Laminated Glass Boiling Test Device

Reference Standard:

- 9) EN ISO 12543-4 Glass in building -Laminated glass and laminated safety glass-Part 4: Test methods for durability – Clause 5 High-temperature test

- 10) AS/NZS 2208 Safety glazing materials in buildings – Appendix F Boil Test

- 11) GB 15763.3 Safety glazing materials in building Part 3: Laminated glass – Clause 7.8 Heat resistance test

- 12) ANSI Z97.1 Safety Glazing Materials Used in Buildings-Safety Performance Specifications and Methods of Test-Clause 5.3.2-(1) Boil Test

- 13) ECE R43 Uniform provisions concerning the approval of safety glazing materials and their installation on vehicles – Clause 5-Test of resistance to high temperature

- 14) ANSI/SAE Z 26.1 American National Standard for Safety Glazing Materials for Glazing Motor Vehicles and Motor Vehicle Equipment Operating on Land Highways-Safety Standard-Clause 5.4 High Temperature

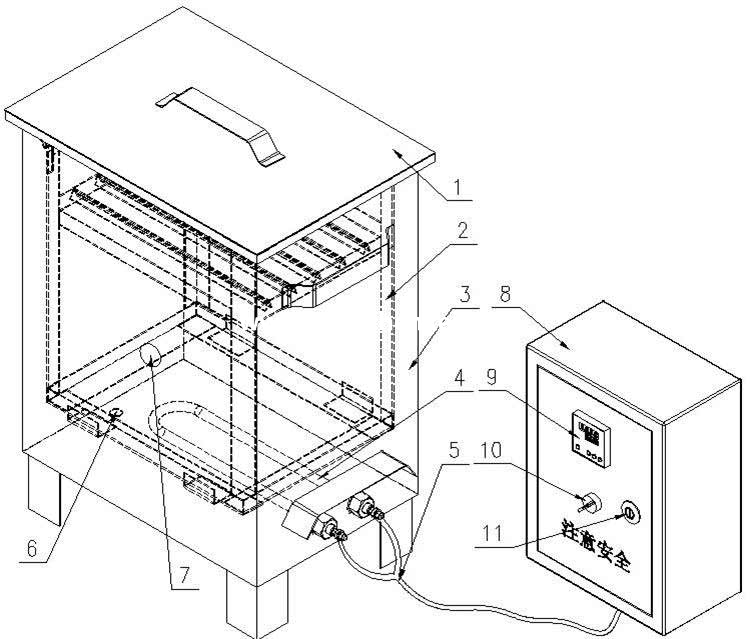

1: Cover 2: Sample Holder 3: Cabine 4: Heating Rod 5: Power Cord 6: Drain Hole 7: Probe 8: Power Distribution Cabinet 9: Temperature Control 10: Power Switch 11: Distribution Cabinet

- Power: 220V 50Hz 3Kw (Customized)

- Outside Size: 430mm*290mm*575 mm

- Inner Size: 400mm*255mm*480mm

- Rack: 340mm*235mm*350mm

- At most 6 samples with 300mm*300mm

Scope:

Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling

Principle:

Specimens are immerse in hot water and boiling water for specified period of time and inspect bubbles and other defects

Apparatus:

The apparatus include two water baths, each of sufficient size to hold the test specimen fully immersed vertically on edge for the duration test

Samples:

Three specimen of size 300mm*300mm manufactured in a manner identical with impact test specimens and of like thickness shall be tested. These specimens may be cut from production samples of the size and thickness submitted for impact testing. Test specimen may be cut from a similar original sheet of annealed laminated glass

Procedure:

1): Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66°C ± 3°C for 3 min

2) Quickly transfer the specimens to a bath of water maintain at boiling point. Immerse the specimens vertically on edge for 2 h

3) Remove the specimens and examine for the bubbles and others defects