PVB Interlayer Boiling Test Device

- PVB Interlayer Boiling Test Device

- Boiling Test Equipment for Heat Resistance of Safety Glazing Materials

- Boil Test device for Safety glazing/glass materials in buildings.

- Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling. 300 mm samples in 66°C for 3 min, and then boiling point for 2 h

Related Standard:

- 1) EN ISO 12543 – 4 Glass in building -Laminated glass and laminated safety glass – Part 4: Test methods for durability – Clause 5 High-temperature test

- 2) AS/NZS 2208 Safety glazing materials in buildings – Appendix F Boil Test

- 3) GB 15763.3 Safety glazing materials in building Part 3: Laminated glass – Clause 7.8 Heat resistance test

- 4) ANSI Z97.1 Safety Glazing Materials Used in Buildings – Safety Performance Specifications and Methods of Test – Clause 5.3.2 – ( 1 ) Boil Test

Data:

- 5) Power: 220V 50Hz 3Kw (Customized)

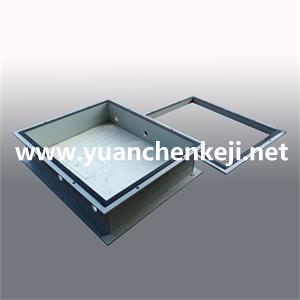

- 6) Outside Size: 430mm*290mm*575 mm

- 7) Inner Size: 400mm*255mm*480mm

- 8) Rack: 340mm*235mm*350mm

- 9) At most 6 samples with 300mm*300mm

6: drain hole 7: Probe 8: Power distribution cabinet 9: Temperature control table

10: power switch 11: Distribution cabinet lock

Scope:

10) Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling

Principle:

11) Specimens are immerse in hot water and boiling water for specified period of time and inspect bubbles and other defects

Apparatus:

12) The apparatus include two water baths, each of sufficient size to hold the test specimen fully immersed vertically on edge for the duration test.

Samples:

13) Three specimen of size 300mm*300mm manufacture in a manner identical with impact test specimens and of like thickness shall be tested.

14) These specimens may be cut from production samples of the size and thickness submitted for impact testing.

15) For heat strengthened or toughened laminated glass, test specimen may be cut from a similar original sheet of annealed laminated glass

Procedure:

16) Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66°C ± 3°C for 3 min

17) Quickly transfer the specimens to a bath of water maintain at boiling point. Immerse the specimens vertically on edge for 2 h

18) Remove the specimens and examine for the bubbles and others defects

Qinhuangdao Yuanchen Technology Equipment Co., Ltd. is mainly engaged in the development, design and processing of sheet metal stamping parts, metal forming molds and building materials inspection and testing equipment.

Main business:

Processing Service:

Laser cutting processing services for various metal plates such as stainless steel, carbon steel, and aluminum alloy.

Sheet Metal Parts:

Automobile stamping parts, construction hardware, railway switch parts, electronic hardware, instrument stamping parts, mechanical equipment hardware and medical equipment sheet metal parts.

Tunnel cable hook

Clothing model hook

Instrumentation shield

Steel structure fasteners

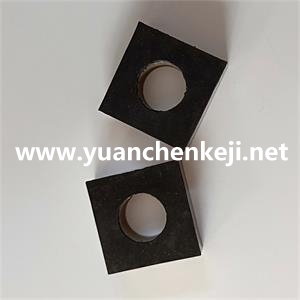

Gasket and retaining ring

Guardrail fence pipe clamp

Wire and cable fixing pipe clamp

Pipe gallery slot embedded parts

Stainless steel stamping shrapnel

Mechanical equipment flange connection

Various sheet metal shells and connectors

Testing Equipment:

Safety glass testing equipment, photovoltaic module testing equipment and various building materials testing and testing equipment.

Ball Test Machine

Shot Bag 45kg/46kg

Pummel Test Machine

Impact Testing Frame

Head Form Test Device

PV Load Test Equipment

Pneumatic Tyres Device

Target Light Source Instrument

Anti Smashing GlassTest Frame

Pneumatic Tyres Impact Device

Insulating Glass Dew Point Meter

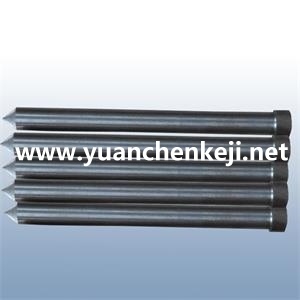

Crushing Pen for Tempered Glass

Hard/Soft Pendulum Shock Test for Lifts

Optical Distortion Measuring Instrument

Hardened Steel Ball 2260g/1040g/508g/227g

Laminated Glass High Temperature Test Oven

Mechanical load test equipment for PV Module

Tempered Glass Flatness Measuring Instrument

Impactor for building Glass and Metal Guardrail

Hard and Soft Body Impactors for Opaque Wall Components

The company has a professional technical team and rich processing experience, with a complete processing and manufacturing system and advanced technology, to meet customer requirements for product quality and provide convenient and efficient services!